Samsung Display Corporation (SDC), one of the world's leading display makers, was spun off from Samsung Electronics in 2012. The company produces a wide range of displays, including LCDs, OLEDs, MicroLEDs and more.

Samsung Display Corporation (SDC), one of the world's leading display makers, was spun off from Samsung Electronics in 2012. The company produces a wide range of displays, including LCDs, OLEDs, MicroLEDs and more.

Samsung Display is the world's leading AMOLED producer by volume, and is also the world's only QD-OLED panel makers. SDC is producing around 500 million AMOLED panels per year (both flexible and rigid panels) used in smartphones, wearables, tablets, laptops and more. The company's QD-OLED panels are used in monitors and TVs.

In addition to its current AMOLED and QD-OLED displays, SDC is developing next-generation OLED technologies, including rollable OLEDs, transparent OLEDs, stretchable displays, OLED microdisplays, and more.

1 Samsung-Ro

Giheung-Gu

Yongin

South Korea

Samsung Display to start producing rollable OLED laptop displays in April 2025, Lenovo is its first customer

Samsung Display unveiled a 18.1" rollable OLED laptop display at CES 2025, one that can roll down to 13.1" when closed. The company today announced that it aims to begin mass producing rollable OLED displays in April 2025. This will mark the first ever mass produced rollable display (apart for the limited volume production of LG's 65" rollable TV screens, that are discontinued).

During CES, Lenovo demonstrated the first laptop to use such a rollable OLED, the ThinkBook Plus G6 Rollable laptop. Lenovo plans to launch it globally in June 2025. The ThinkBook Plus G6 Rollable will have a 14" 5:4 display when rolled in, and a 16.7" 8:9 display when opened. That's an increase of almost 50% in screen size. The price of Lenovo rollable laptop will start at $3,499 - this is a ultra premium device.

Samsung Electronics announced its 2025 OLED TV range

Samsung Electronics announced its 2025 OLED TV range, with three different series. The TVs use a combination of SDC's QD-OLED panels (latest generation that reaches 4,000 nits) and LGD's OLEDs.

The top of the range is the S95F, Samsung's flagship 2025 TV, that will be available in 55", 65", 77" and 83" sizes. The S95F offers 4K 165hzQD-OLED panels (except the 83-inch model which uses LG's WOLEDs, apparently). The S95F TVs use Samsung's new NQ4 AI Gen3 video processor.

Samsung Display shows new OLED technologies at CES 2025

Samsung Display is set to show new OLED technologies at CES 2025, including new foldable display, rollable ones, automotive displays, next-gen QD-OLED panels and more.

So first up, Samsung will be showing a 18.1 foldable OLED display (which it says is the world's largest). This panel is suitable for IT devices - to enable devices that combine tablet, laptop and monitor devices into one. When folded, this display is 13.1" in size.

Samsung Display signs a strategic partnership with Dolby to improve its automotive OLED displays

Samsung Display announced today a strategic partnership with Dolby Laboratories, to offer SDC's automotive displays which are pre-tuned to deliver Dolby Vision to automotive makers.

Samsungs says that by implementing a new streamlined evaluation and implementation process it will be able to offer best-in-class imaging experiences for automotive displays.

UBI Research: the OLED emitter market reaches a new high in Q3 2024

UBI Research estimates that the volume of OLED emitting materials purchased in Q3 2024 reached 32.7 tons, which is the highest ever, with the previous record in 2021. UBI expects 2024 as a whole to be the record year in OLED emitter material shipments.

In terms of customers, SDC holds the largest share with 41.4% of the total market, followed by LGD (20.5%), BOE (11.6%) and Visionox (8.3%). In terms of architecture, 83.7% of all emitter materials went into RGB OLEDs, 11.3% into WOLED (LG's WRGB) panels and 2.8% into QD-OLED panels.

Samsung may convert its 5.5-Gen A2 OLED fab to a microdisplay production line

A few weeks ago it was reported that Apple is aiming to develop a lower-cost VR headset, and will want to use cheaper OLED microdisplays to replace the high-end Sony OLED microdisplays used in the Vision Pro. It was reported that both Samsung and JDI are in talks with Apple, that aims to achieve a pixel density of 1500 PPI (the Sony microdisplays sport 3,400 PPI). Samsung meanwhile develops its own headsets, and is also working on solutions for other leading companies, such as Microsoft.

A 1.3" 12000 nits OLED microdisplay (Samsung Display)

A 1.3" 12000 nits OLED microdisplay (Samsung Display)

While Samsung is working on an OLED on silicon microdisplay factory, the company is also looking to start producing high resolution AMOLED displays on glass. According to a new report, Samsung is now looking to build a new AMOLED on glass microdisplay pilot production line in Asan, and later on the company is considering to converts its 5.5-Gen (1300x1500 mm) A2 OLED production line to produce OLED microdisplays. Samsung will have to modify its production process and install new equipment to support the high resolution. The company reportedly aims to order the required equipment in 2025.

UBI: Samsung's automotive OLED shipments rise, but sales of tablet OLED displays are soft

UBI Research says that Samsung Display's medium and large OLED panel shipments in Q3 2024 were the same as in the previous quarter. Shipments of tablet OLED devices were low, but this was offset by increased sales of automotive displays. Compared to 2023, total medium and large OLED panel shipments more than doubled, mainly due to increased sales of tablet panels to Apple, and increased laptop OLED shipments.

UBI estimates that SDC's tablet PC sales decreased by 38% compared to the previous quarter. Automotive OLED shipments rose from 100,000 units in Q1 2024 to around 500,000 in Q3.

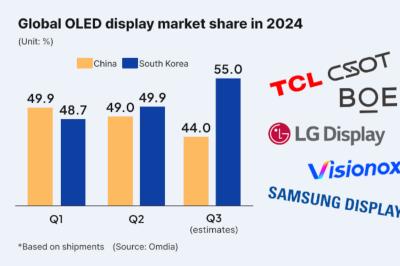

Omdia: Korea retakes the top position in OLED shipments in Q2 2024, as Samsung and LG aim to widen the technology gap with Chinese rivals

According to Omdia, Korea regained the top position in the AMOLED market in Q2 2024, after China surpassed Korea in Q1 2024 for the first time.

Omdia says that both Samsung Display and LG Display enjoyed increased sales of high-end AMOLED displays for IT devices (laptops and tablets), and held a market share of 49.9% in Q2 2024, while Chinese OLED makers (Visionox, BOE, Everdisplay, Tianma and CSoT) held a market share of 49%.

UBI: Apple reduces its iPad AMOLED orders from Samsung and LG as demand for its tablets is low

UBI Research estimates that Apple suffers from poor demand for its iPad Pro devices, and the company has reduced its orders from LG Display and Samsung Display. We heard signs of that already back in August.

UBI estimates that LG Display's medium to large sized OLED panels shipments decreased 34% in Q3 2024, compared to the previous quarter. Samsung Display's tablet OLED panel sales dropped 38% in the quarter. Samsung however enjoyed higher sales of automotive OLEDs, which means that its entire medium-to-large sales were flat in the quarter.

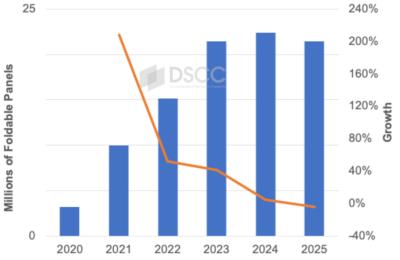

DSCC: The foldable smartphone market will stagnate in 2024 and 2025, fast growth will continue in 2026

According to DSCC, the foldable smartphone display market has declined for the first time in Q3 2024, and the company sees the market entering a flat state in 2024 and 2025. The market has grown fast (at least 40% per year) since 2019, but according to DSCC it will grow only 5% in 2025 and will decline by 4% in 2025. Demand will remain stable at around 22 million units per year.

DSCC says that Samsung is seeing slower than expected demand for its Galaxy Z Flip 6 smartphone, around 10% lower than the Z Flip 5 released in 2023. Almost all of Samsung's demand is in the Korean and Europrean markets. Huawei has also placed lower than expected orders for foldable OLEDs for the second half of 2024, due to the late introduction of the Mate X6 and Pocket 3 devices compared to the 2023 launch dates. The demand for its tri-foldable Mate XT is lower than expected as well.

Pagination

- Page 1

- Next page