Applied Materials launches a maskless OLED production technology, to support 8-Gen high efficiency OLED deposition and encapsulation

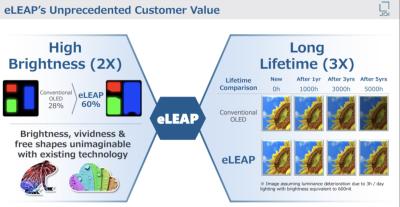

Applied Materials announced a technology, branded as MAX OLED that enables OLED display production on large glass substrates, aiming to provide a cost-effective solution to produce TV and TV displays. Applied developed and patented a new OLED pixel architecture and a "dramatically different manufacturing approach" that the company says enables brighter, clearer, more energy-efficient and longer-lasting.

Applied's new MAX OLED systems can scale from 6-Gen substrates to 8-Gen substrates, supporting the new wave of IT OLED production lines. Applied says that its new solution has strong customer interest - and already achieved repeat orders from several leading display makers (see below). Specifically, Applied announced that it will supply an R&D system to Samsung Display that will test the new production technology for its AMOLED and QD-OLED production technologies.