eMagin introduce the new OLED-XLS series, the world's brightest full-color OLED microdisplays

eMagin unveiled the world's brightest full-color OLED microdisplays, the color OLED-XLS series. Those displays offer 1000 nits of luminance, that is four times brighter than "current industry standard".

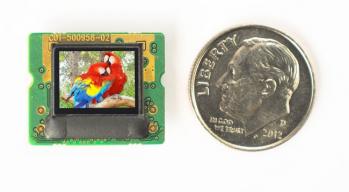

XGA096 OLED-XL

XGA096 OLED-XL

eMagin are currently offering OLED-XLS displays in sample quantities over their entire product line (VGA, SVGA, XGA, SXGA and WUXGA). They will continue to produce the "older" OLED-XL displays.