Guo, an associate professor of Electrical Engineering & Computer Science at the University of Michigan, has come up with semitransparent metal electrodes, fabricated by nanoimprint lithography (NIL), that, with further optimization, could replace today's use of conventional ITO electrodes in OLEDs. The core findings of this research is that a nanowire metal grid can provide sufficient optical transparency and electrical conductivity for it to be used as a transparent electrode for organic optoelectronic applications. These metal electrodes contain no expensive metallic elements and do not suffer from atomic diffusion but are nevertheless very efficient.

Guo, an associate professor of Electrical Engineering & Computer Science at the University of Michigan, has come up with semitransparent metal electrodes, fabricated by nanoimprint lithography (NIL), that, with further optimization, could replace today's use of conventional ITO electrodes in OLEDs. The core findings of this research is that a nanowire metal grid can provide sufficient optical transparency and electrical conductivity for it to be used as a transparent electrode for organic optoelectronic applications. These metal electrodes contain no expensive metallic elements and do not suffer from atomic diffusion but are nevertheless very efficient.

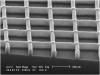

Guo and his team based their new electrodes on a densely perforated thin film of metal supported on a glass layer. The perforations make the metal layer almost transparent, which means it can be the top electrode in an OLED. Moreover, they can fine-tune the fabrication process to make the perforations smaller or larger and to change their spacing. This allows them to adjust the transparency at different wavelengths of light allowing different colors to predominate. Most importantly though, NIL can be used to make an electrode with an enormous area, far bigger than a cellphone display, and so open up OLED technology to a much wider range of applications, including windows and giant screen TVs.