OLED ink jet printing: introduction and market status - Page 10

JOLED to show new printed OLED monitors and TV prototypes at Finetech Japan

Last month Japan-based printed OLED developer JOLED announced that it will demonstrate new OLED prototypes (including a 55" printed OLED TV) at Finetech Japan, which starts tomorrow (December 5). Today JOLED detailed the new panels it will have on display at the trade show.

So first we have two automotive displays - a 12.3" HD OLED and a 12.2" flexible (curved ) Full-HD OLED. JOLED's latest investors, Denso and Toyoto Tsusho, are both helping the company with its entry into the automotive display market.

CSoT breaks ground on its upcoming T7 fab, which includes a printed OLED TV line

China-based display maker CSOT held a ceremony yesterday as it started construction on its upcoming T7 large-area display production fab. The T7 fab, which has a total cost of around 42.7 billion Yuan ($6.15 billion USD), will produce both LCD and OLED displays.

Total capacity in the T7 line will be 105,000 monthly substrates (according to our information, the OLED capacity will be 20,000 monthly substrates). The T7 OLED line will use IGZO backplanes and inkjet printing deposition. CSOT's plan is to start production by the end of 2020 - with real mass production starting in 2021.

BOE demonstrates its first ink-jet printed OLED TV prototype

BOE is hosting its Global Innovation Partner Conference 2018 (BOE IPC-2018, which invited experts from all over the world to see BOE's latest technology and future trends.

During the event, BOE unveiled an ink-jet printed 55" UHD OLED TV prototype. This is the first time that BOE demonstrated an ink-jet printed TV (in May 2018 BOE unveiled 5.5" FHD flexible AMOLED which was also produced using a printing process).

JOLED to demonstrate a 55" ink-jet printed OLED TV next month

Japan-based printed OLED developer JOLED announced that it will demonstrate a 55" 4K printed OLED TV at Finetech Japan 2018 (December 5-7 2018). JOLED will also introduce its proprietary printed OLED manufacturing technology. A few weeks ago JOLED announced that it has signed an agreement to develop, manufacture, and sell printing equipment together with Panasonic and Screen Finetech.

This is the first time JOLED will show a 55" OLED prototype (in July 2018 the company did include TVs in its future roadmap). JOLED tells us that it has no plans to produce large size OLEDs at this stage - and this TV is on display just to demonstrate JOLED's printing technology.

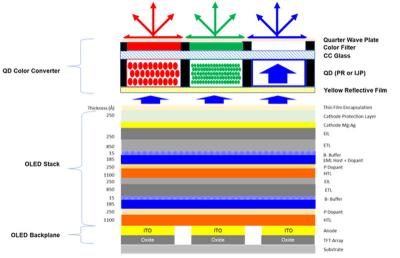

Digitimes details Samsung's QD-OLED TV production plans and equipment

Samsung Display is developing hybrid QD-OLED TV technology, and according to estimates, the company aims to begin trial production in 2019. It is also estimated that Samsung has several challenges to overcome, but according to new reports from Digitimes, Samsung is aiming to start installing equipment for the new fab as early as December 2018.

The new fab will begin operation in the second half of 2019 - pilot production at first which will be expanded to full scale mass production. The new fab will be built in Samsung's L8 LCD production line in Asan, and will take over one of the two lines currently in operation at the fab. Samsung's initial production capacity will be around 25,000 monthly G8 substrates.

AUO to establish an OLED ink-jet production line, to make OLEDs for monitors and automotive applications

According to reports from China, Taiwan-based AU Optronics decided to establish an inkjet OLED production line that will be used to produce OLED monitor displays and OLEDs for automotive applications.

The new OLED line will use production equipment made by Japan's JOLED - who started commercial low-volume production of its own 21.6" 4K OLED panels, at the company's pilot 4.5-Gen line. JOLED also announced plans for a mass production 5.5-Gen line that will be established in Nomi City, Ishikawa Prefecture, by 2020, and similarly to AUO, it is focusing on monitors and automotive applications.

The EU-funded Flexolighting project believes that OLED lighting cost can be reduced to 1 Euro per 100 lumens

In 2015, the EU launched the â¬4.4 million Flexolighting project (led by Brunel University London) with an aim to develop new materials, processes and methods to overcome current OLED lighting challenges - including lifetime, lighting uniformity and more.

The project's consortium announced that following the project completion and a rethinking of the complete OLED supply chain, it believes that high efficiency OLED lighting panels can be produced at a cost that is on a similar level with LED lighting.

JOLED, Panasonic and Screen Finetech to co-develop and sale OLED printing equipment

JOLED announced today that it signed an agreement with Screen Finetech Solutions and Panasonic Production Engineering to co-develop, manufacture and sale printing equipment for large-area OLED production (mostly OLED TVs).

The three companies aim to quickly commercialize a new business that will be based on JOLED's manufacturing technology. JOLED plans to license its inkjet printing technology to OLED makers. JOLED has been developing its technology in collaboration with Panasonic since its founding in 2015. JOLED's technology was originally developed in Panasonic at around 2006.

JOLED raises $400 million - half of what it needs to establish its first printed OLED mass production line

Last month Japan-based OLED maker JOLED announced official plans for its first mass production printed OLED fab, and today it is reported that JOLED have raised around $400 million from four new investors - auto parts maker Denso ($270 million), major trading house Toyota Tsusho ($90 million) and Sumitomo Chemical and Screen Holdings.

JOLED intends to raise $900 million, so the current amount is less than half of what it needs to complete its first mass production line. According to earlier reports, Panasonic and Sony also intend to to invest around $50 million each.

JOLED announces official plans for a 5.5-Gen printed OLED fab in Ishikawa, Japan

Towards the end of 2017, JOLED started commercial production of its 21.6" 4K OLED panels. But this is very low volume production (at JOLED's pilot 4.5-Gen line) as the company said it is seeking to raise $900 million to support its plan to start mass producing OLEDs in 2019.

Today JOLED announced official plans for its first mass production printed OLED fab. JOLED will establish the production site in Nomi City, Ishikawa Prefecture. The capacity of the new fab will be 20,000 monthly 5.5-Gen (1300x1500 mm) substrates and the plan is to begin mass production in 2020. JOLED will produce 10- to 32-inch OLED displays for automotive displays, high-end monitors and more.

Pagination

- Previous page

- Page 10

- Next page