OLED Encapsulation: introduction and market status - Page 11

LGD adopted Mitsui Chemicals' transparent OLED sealant in its flexible OLED displays

Mitsui Chemicals announced that its Structbond XMF-T transparent OLED sealant is used in LGD's flexible OLED displays (the 6" 720p plastic-based flexible OLED as used in the G Flex curved smartphone).

Mitsui says that their sealing material offers high barrier properties, moisture resistance, transparency and process manageability.

LG Chem to cut OLED lighting prices by over 60%

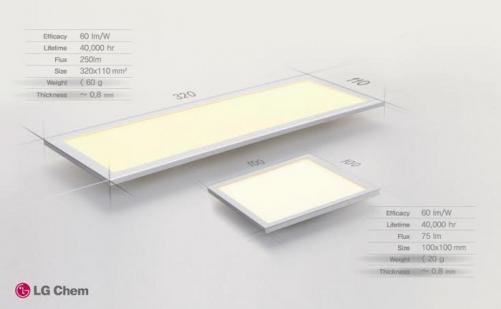

LG Chem announced today that they are going to cut the prices of their OLED panels at Q3 2014. LG Chem is aiming to cut their prices by about 60% (!) - from about $600/Klm to about $200/Klm. LG Chem will offer these prices at first to selected prices that are willing to "stimulate the market with mass-production of OLED luminaires".

LG Chem explains that this price drop was possible because the company changed the glass substrate and the encapsulation materials in their production process. This enables them to create thinner, light and cheaper panels without any effect on the performance. LG Chem will first upgrade and lower the price of their popular 100x100 mm and 320x110 mm panels, and later on they will upgrade all of their panels.

Goto Denshi offers an OLED encapsulation patent portfolio for sale

Patent broker ICAP announced that on May 27 it will launch a new sale for an OLED IP package. This is an OLED patent portfolio developed by Japan's Goto Denshi that discloses a technique for OLED encapsulation. The portfolio includes 5 assets - 3 patents (in the US - patent #8,487,532, Russia and Japan) and 2 patent applications (In the US and Japan).

ICAP says that the patents describer a two-layer sealing technique which envelops an OLED display panel with an impermeable resin. ICAP says that this technology (which is applicable for both OLED display and lighting panels) not only provides a good barrier, but is also scalable to large screen sizes and mass production processes. The initial bidding guidance is low to mid 6 figures.

COMEDD developed flexible OLED lighting panels on flexible glass

Fraunhofer COMEDD is looking to advance flexible OLED lighting device lifetime, and towards that goal the German institute developed flexible OLED lighting panels on flexible glass substrates. COMEDD reports that flexible glass can enable curved panels that has high OLED lifetime - much higher than can be obtained with polymer-based encapsulation and substrate technologies.

Fraunhofer developed those new panels on their own Roll-to-Roll R&D line in collaboration with Von Ardenne (on the development of process equipment) and Nippon Electric Glass (they provided the "G-Leaf" flexible glass rolls). The G-Leaf glass is less than 35 um thick and can be used in roll-to-roll processes.

New Vision developed a new 5" flexible AMOLED on a PEN substrate

In 2013, Guangzhou New Vision Optoelectronics (New Vision) developed a flexible 4.8" AMOLED display using an Ln-IZO backplane and a polyimide substrate. New Vision now unveiled another flexible AMOLED prototype, this one using a PEN substrate. The company says that they expect flexible OLEDs to be commercialized in the near future.

The new full-color display is 5-inch in size with a thickness of only 0.1 mm and a weigh of less than 5 grams. The radius of curvature is up to 1 cm. New Vision says that PEN is preferable to Polyimide because it's cheaper, it doesn't require the complex preperation process required by PI and it enables transparent panels. The PEN substrate limits the production temperature to 180 C which created a major challenge for New Vision (to deposit the Oxide-TFT backplane at that temperature).

Veeco sees a slowdown in flexible OLED production plans at SDC

In September 2013, Veeco acquired Synos Technology for $185 million for the company's FAST-ALD flexible OLED encapsulation technology. Veeco later received a purchase order from SDC for a first-generation FAST-ALD prototype system. Veeco expected a manufacturing ramp to begin in 2014 - hoping to book more than $75 in ALD production systems by the end of the year.

Yesterday Veeco reported their financial results for Q1 2014. While the company had a good quarter (revenues of $91 million, up 24% sequentially) the new OLED business did not perform as good as they expected. In fact, they didn't get the orders they thought they'd get in Q1 2014, which meant that Veeco will pay less for Synos - $25 million less, actually.

Encapsulix reveals that Blackbody is their OLED ALD encapsulation customer

In October 2013, Encapsulix announced that a "leading OLED lighting supplier in Europe" placed an order for the M500 ALD deposition system. The deposition system shipped in February 2014 and today Encapsulix updated us that the system was installed successfully - and that the customer is Blackbody (Astron Fiamm Safety).

Blackbody will use the new system to deposit OLED encapsulation for panels used in the residential, commercial, automotive and avionics markets. Encapulix's system can process substrates up to 400x500 mm in size and is well suited for Blackbody's Gen-2 production line. Blackbody will also use this system to develop other coating (not just encapsulation layers).

MBraun and Beneq to jointly develop turn-key OLED R&D systems

MBraun and Beneq announced that the two companies joined forces to provide complete turn-key systems for OLED R&D. The two companies will tailor R&D systems for customers that need research equipment int he areas of thin-film encapsulation and inert-gas glove box technologies.

OLED encapsulation is a hot topic, with several companies including Veeco, Beneq and Encapsulix developing and supplying ALD-based solutions. In October 2013 we published an interview with Beneq's technical sales Director.

Picodeon develops ultra-short pulsed laser deposition for OLED encapsulation

Picodeon developed its its ultra-short pulsed laser deposition (USPLD) surface coating technology to be able to coat OLED encapsulation layers on plastic substrates at low temperatures. The company's systems can be used to create either porous or dense aluminium oxide (Al2O3) coatings (also other metallic and oxide coatings).

Picodeon's Al2O3 coatings can be applied on polyethylene (PE) and thermoplastic polyurethane (TPU) polymer film substrates. Picodeon’s recently released ColdAb Series4 equipment (shown above) is currently being installed in commercial applications.

LG Chem launches the world's largest OLED lighting panel at 320x320 mm

LG Chem announced the world's largest OLED lighting panel at 320x320 mm (and it's only 1 mm thick!). The N6SD30 features 60 lm/W, 850 lumens brightness (max 1,000), a high CRI (>90) and a color temperature of 3000K.

The lifetime of the N6SD30 is 40,000 (LT70) at 3,000 cd/m2. LG Chem says they managed to extend the panel's lifetime (compared to their older panels) mainly by using the company's own Face Seal encapsulation technology. In fact, LG Chem upgraded all of their OLED panels to feature this new encapsulation and so all of their panels now feature 40,000 (LT70) lifetime hours.

Pagination

- Previous page

- Page 11

- Next page