Integrating MOFs and Organometallic complexes with OLEDs offers improved efficiency, stability, and performance, providing opportunities for novel applications of OLEDs in market areas such as sensing, energy storage, and optoelectronic devices.

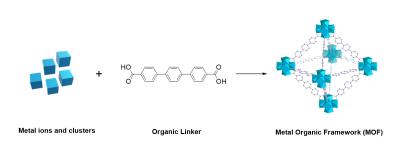

What is a MOF?

Metal-Organic Frameworks (MOFs) are a class of materials that consist of metal ions or clusters coordinated to organic ligands to form one-, two-, or three-dimensional structures. Incorporating various metal ions into MOFs can significantly influence their electronic, optical, and structural properties, making them suitable for applications such as Organic Light-Emitting Diodes (OLEDs).

Using MOFs with OLEDs - Breakthrough Value-Add and New OLED Markets via Improved Efficiency, Stability and Performance:

Enhanced Electron Transport: MOFs can serve as electron transport materials in OLEDs, facilitating the movement of electrons within the device. By improving electron transport, MOFs can enhance the efficiency of OLEDs, leading to brighter and more energy-efficient displays or lighting panels.

Improved Stability: MOFs with robust structures can help improve the stability of OLED devices. They can serve as protective layers or barriers, shielding the organic layers of the OLED from environmental factors such as moisture and oxygen, which can degrade the performance of the device over time. This can extend the lifetime of OLED products and reduce maintenance costs.

Tuneable Properties: The tuneable nature of MOFs allows for the customization of their properties to suit specific OLED applications. Researchers can design MOFs with tailored electronic, optical, and structural properties to optimize their performance within OLED devices. This flexibility enables fine-tuning of OLED characteristics such as colour purity, efficiency, and operational lifetime.

Compatibility with Solution Processing: Many MOFs can be synthesized using solution-based methods, making them compatible with the solution processing techniques commonly employed in OLED fabrication. This compatibility simplifies the integration of MOFs into OLED manufacturing processes, potentially reducing production costs and enabling large-scale production of OLED devices.

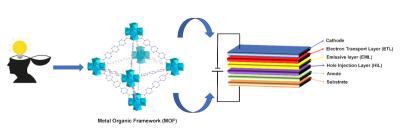

Versatility in Device Architecture: MOFs can be incorporated into various layers of the OLED device structure, including the emissive layer, electron transport layer, or as encapsulation materials. This versatility allows for the optimization of different aspects of OLED performance, such as charge injection, recombination efficiency, and light outcoupling, leading to overall device improvements.

Potential for Novel Properties: Some MOFs exhibit unique properties, such as luminescence or photoconductivity, which could be harnessed to create novel OLED architectures with enhanced functionality. For example, luminescent MOFs could be used as emitters or hosts in OLEDs, offering opportunities for new device designs and applications.

Potential for Multifunctionality: The MOFs can be tailored to possess additional functionalities beyond light emission, like charge transport properties, gas adsorption capabilities or catalytic activity. The multifunctionality opens up opportunities for integrating various functionalities into OLEDs, enabling innovative applications beyond conventional displays and lighting.

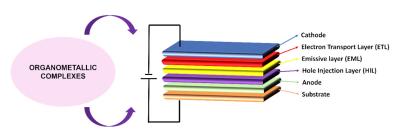

Value-Add with Organometallic Complexes in OLEDs:

Improved Efficiency: Organometallic complexes offer the potential for higher quantum efficiency and brightness in OLEDs compared to traditional organic emitters. Researchers continue to explore novel molecular structures and design strategies to maximize the efficiency of these complexes.

Expanded Color Range: Organometallic complexes can be engineered to emit light across a broad spectrum, enabling the creation of OLED displays with vibrant and accurate colors. Advances in molecular design allow for precise control over the emission wavelength, facilitating the development of displays with expanded color gamut.

Enhanced Stability: Stability is a crucial factor for the commercial viability of OLED technology. Organometallic complexes with improved thermal and chemical stability are being developed to address degradation mechanisms that can limit the lifespan of OLED devices. This includes strategies to mitigate degradation due to oxygen and moisture exposure, as well as photodegradation.

Flexible and Wearable Applications: OLEDs with organometallic complexes are well-suited for flexible and wearable applications due to their thin, lightweight, and bendable nature. These materials enable the fabrication of OLEDs on flexible substrates, allowing for the creation of curved or rollable displays, as well as conformal lighting panels for wearable devices.

Energy-Efficient Lighting Solutions: As the demand for energy-efficient lighting continues to grow, OLEDs with organometallic complexes offer a promising solution. These materials can achieve high luminous efficacy and color quality, making them suitable for various lighting applications, including architectural lighting, automotive lighting, and portable lighting devices.

Manufacturing Advances: Advances in manufacturing processes and deposition techniques are making it easier to integrate organometallic complexes into OLED devices. Solution-based processing methods, such as inkjet printing and organic vapor-phase deposition, allow for the scalable and cost-effective production of OLEDs with complex architectures.

Longer Lifespan: The synthesized phosphorescent complexes tend to have longer excited-state lifetime when compared to the fluorescent materials. This property enables more efficient energy transfer processes and at the same time also reduces the scope of non-radiative decay, resulting in improved OLED device stability and lifetime.

Beyond traditional display and lighting applications, OLEDs incorporating organometallic complexes are being utilized in emerging fields such as optoelectronic sensing, photovoltaics, and biomedicine. These materials possess unique optical and electronic properties that enable innovative functionalities across diverse applications.

In summary, incorporating these metal ions into MOFs offers a versatile platform for designing OLED materials with tunable properties. The choice of metal ion can significantly influence the electronic conductivity, luminescence, and structural stability of the MOF, allowing for the optimization of OLED performance.

MOFs offer numerous advantages and exhibit unique properties making them well-suited for OLEDs:

a) Carrier Injection and Transport: MOFs have the ability to facilitate charge injection and transport due to their intrinsic electronic properties and well-defined structures. Hence, they can be used as a host material or as a component in the emissive layer of OLEDs.

b) Emissive Materials: Most importantly, the MOFs can be functionalized with different luminescent molecules to serve as emissive materials in OLEDs. These luminescent MOFs (LMOFs) can in turn exhibit tunable emission properties including colour and intensity based on the choice of metal ions and organic linkers.

c) Enhanced Light Extraction: The porous nature of MOFs can facilitate light extraction in OLEDs by trapping and scattering light within the device structure.

d) Stability and Encapsulation: MOFs can serve as the protective layers or encapsulants for OLED devices, offering improved stability against environmental factors like moisture and oxygen. The device’s lifetime and reliability get increased on coating OLEDs with MOF thin films, thus making them suitable for various applications like displays and lighting.

e) Hybrid Structures: MOFs can be combined with other functional materials like polymers or quantum dots to create novel OLED architectures. These hybrid systems can synergistically combine the unique properties of MOFs with those of other materials, resulting in enhanced device performance and functionality.

f) Versatile Chemistry: A wide range of metal ions and organic ligands can be utilized for synthesizing MOFs, thereby offering flexibility in tailoring both electronic and optical properties. These materials can be further modified with desirable luminescent characteristics like colour tunability and high photoluminescence quantum yields.

g) Tailorable Structure and Pore Size: The versatile nature of MOFs with tunable structures pore sizes makes them suitable materials for OLED applications as these can efficiently control the transport of charge carriers and optimize light emission properties.

h) High Surface Area: MOFs exhibit high surface area, thereby enhancing the interaction between the emissive materials and charge carriers within the OLED device. This results in improved charge injection, transport and recombination, which finally results in enhanced device efficiency and performance.

i) Gas Adsorption Capabilities: MOFs adsorb and desorb small molecules, which help in mitigating issues like quenching of luminescent species or degradation of OLED materials due to exposure to environmental contaminants.

j) Potential for Hybrid Systems: Multifunctional OLED devices can be created by integrating MOFs into hybrid structures like organic semiconductors or quantum dots which exhibit synergistic effects, resulting in improved device performance and functionality.

k) Environmental Sustainability: Most of the MOFs consist of abundant and environment friendly elements, which makes them ideal candidates for sustainable optoelectronic applications. The tunable properties of MOFs enable the design of more energy-efficient OLED devices, which in turn results to environmental sustainability.

Challenges and Disadvantages with current OLED technologies:

- Limited lifespan compared to some other display technologies, particularly with blue OLEDs.

- Manufacturing costs can be high due to complex production processes and material expenses.

- Susceptibility to water and oxygen degradation, requiring encapsulation techniques to improve durability.

- Efficiency droop at high brightness levels, where the efficiency of OLEDs decreases as the current density increases. Vulnerable to image burn-in, especially for static images displayed for extended periods.

- Issues with uniformity and color consistency across large displays.

- Concerns about the use of rare earth metals and their environmentally sensitive materials in OLED production.

Integrating MOFs and Organometallic complexes with OLEDs offers improved Efficiency, Stability, and Performance, providing opportunities for novel applications of OLEDs in market areas such as sensing, energy storage, and optoelectronic devices.

Who is Viva Bio?

Viva Bio develops biotechnology solutions to solve the high mortality rate problems harming the global population. Our initial developments include a drug-delivery system with uses in targeted cancer drug delivery as well as opioid overdose intervention. Along the way, we have developed hundreds of MOF compounds which can provide substantial value to the OLED industry. Viva Bio would like to license these compounds to your business and can also develop custom compounds to suite your OLED needs and help you expand the potential OLED market!

Contact Viva Bio:

(203)-219-8878

david@vivabiotechnology.com

www.vivabiotechnology.com

References

1. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10862192/

2. DOI: 10.13140/RG.2.2.17010.71360

3. DOI: 10.1002/advs.202002254

4. https://doi.org/10.1016/j.ccr.2019.213077

5. https://doi.org/10.1016/j.ccr.2018.01.017, Polymers 2020, 12, 691;

6. DOI:10.3390/polym12030691

7. DOI: 10.1021/acs.chemrev.5b00074

8. https://www.mdpi.com/2673-4591/56/1/146

9. Liu, B.; Vikrant, K.; Kim, K.-H.; Kumar, V.; Kailasa, S.K. Critical role of water stability in metal–organic

frameworks and advanced modification strategies for the extension of their applicability. Environ. Sci.

Nano 2020, 7, 1319–1347

10. Liu, X.; Wang, X.; Kapteijn, F. Water and Metal–Organic Frameworks: From Interaction toward

Utilization. Chem. Rev. 2020, 120, 8303–8377.

11. Forgan, R.S. The surface chemistry of metal–organic frameworks and their applications. Dalton

Trans. 2019, 48, 9037–9042.

12. Bavykina, A.; Kolobov, N.; Khan, I.S.; Bau, J.A.; Ramirez, A.; Gascon, J. Metal–Organic Frameworks in Heterogeneous Catalysis: Recent Progress, New Trends, and Future Perspectives. Chem. Rev. 2020, 120, 8468–8535. https://doi.org/10.1021/acs.organomet.9b00539

13. DOI: 10.1021/acs.organomet.9b00539 Organometallics 2019, 38, 3389−3391

14. Coatings 2020, 10(3), 277; https://doi.org/10.3390/coatings10030277

15. https://doi.org/10.1002/gch2.202300244

This was a sponsored post by Viva Bio