Mitsubishi is a "community" that consists of a multitude of independent companies involved in a wide range of markets including automobiles, plastics, electronics, hotels, banking and more. Several of these companies were involved with OLEDs, but most (not all) of Mitsubishi's OLED projects were cancelled.

Mitsubishi is a "community" that consists of a multitude of independent companies involved in a wide range of markets including automobiles, plastics, electronics, hotels, banking and more. Several of these companies were involved with OLEDs, but most (not all) of Mitsubishi's OLED projects were cancelled.

Mitsubishi Chemicals was working towards OLED materials together with UDC. They had also entered the OLED Lighting market together with Pioneer in 2010 and were selling OLED panels under the Verbatim brand (Verbatim is owned by Mitsubishi Chemicals), but the OLED lighting business was later disbanded. The company developed (in collaboration with researchers from Keio University) a new method to accelerate the design of OLED materials, using a combination of classical computing with quantum computing.

Mitsubishi Heavy Industries aimed to produce OLED display panels back in 2007, but that project never saw the light of day.

Mitsubishi Electric was producing the world's largest OLED display, the Diamond Vision OLED, modular displays that are made from 128x128 PMOLED tiles. The first Diamond Vision OLED was installed in 2010 at Merck's Material Research Center, and several others were announced, but it seems that product line has been abandoned. Mitsubishi Electric also had an extensive display IP portfolio (over 1,200 patents related to LCD, OLED and other display technologies) - which it sold to IPValue in 2024.

1-1 Marunouchi 1-chome

Chiyoda-ku

Tokyo

100-8251

Japan

Mitsubishi Chemical, Deloitte Tohmatsu and Classiq manage to dramatically improve the OLED material discover efficiency of quantum computing

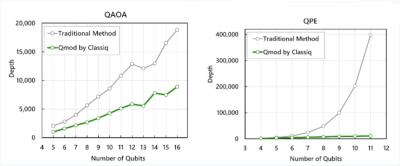

Mitsubishi Chemical has disclosed that it has long been developing Quantum Approximate Optimization Algorithms (QAOA) for the development of advanced OLED emitter materials. One of the main challenges in this route has been that calculation accuracy that could not be guaranteed due to the accumulation of noise that affected the state of the quantum computer.

Mitsubishi Chemical has thus teamed up with Deloitte Tohmatsu and Classiq to compress the two quantum circuits used by Mitsubishi Chemical. The three companies managed to demonstrate up to 97% compression in the size of the first circuit and up to 54% on the second circuit. This dramatic compression will enable more accurate calculations as it mitigates the risk of errors during calculation.

Researchers combine classical computing with quantum computing to discover promising OLED emitters

Researchers from Japan's Keio University, in collaboration with Mitsubishi Chemical Corporation, developed a new method to accelerate the design of OLED materials, using a combination of classical computing with quantum computing.

The new approach combines a 'classic' machine learning model with a quantum-classical computational molecular design. Demonstrating the new approach, the researchers discovered a highly efficient OLED emitter, a deuterated derivative of Alq3. The new emitter is not only highly efficient, it is also easy to synthesize.

IPValue acquires over 1,200 display related patents from Mitsubishi Electric

IP Portfolio holder IPValue Management acquired over 1,200 patents and applications from Mitsubishi Electric's display business unit. The IP, a result of over two decades of R&D, encompasses a wide range of LCD, OLED and other technologies.

The patents will now be owned by IPValue's subsidiary, Trivale Technologies. The financial terms of this agreement were not disclosed.

Mitsubishi and Pioneer to start mass producing color-tunable OLEDs made using a wet-coating process

Mitsubishi Chemical Corporation Pioneer Corporation have developed a color-tunable and dimmable OLED lighting panel produced using Mitsubishi's wet-coating process. The companies say that this panel can be produced for less than one-third of the cost of OLEDs made with regular evaporation-based production methods.

Mitsubishi and Pioneer say that these panels will be mass produced in early 2016. They will make three panels, the OLE-P0505 (55x55 mm, active area 40x35 mm), the OLE-P0707 (69x69 mm, active area 54x51 mm) and the OLE-P0909 (92x92 mm, active area 76x76 mm). All three panels are 1.08 mm thick and feature a max luminance of 2,000 cd/m2 and a color temperature of 3000K to 5000K. The panels will be distributed by MC Pioneer OLED Lighting Corporation.

Mitsubishi and Pioneer launched bluelight-less OLED lighting panels

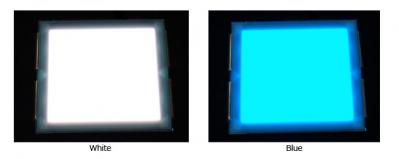

Mitsubishi Chemical and Pioneer announced that they developed a bluelight-less OLED lighting panel. The OLE-P0909-C3S module which contains this panel is actually already shipping, and it is produced using the wet-coating process developed by the two Japanese companies.

The new panel emits a minimal portion of blue light - less than 1% of the amount emitted by Mitsubishi and Pioneer's regular 3000K OLED panel. The panel is a candle-color type - with a 1900K color temperature. The module size is 92.4x92.4 mm (active area 76x76 mm) and is 4.3 mm thick. The maximum luminance is 3,000 cd/m2.

Mitsubishi doubles the lifetime of their wet-coating OLED lighting panels

In early 2014, Pioneer and Mitsubishi Chemical announced that they began to mass produce OLED lighting modules made with a "wet coating system". Soluble OLED processes should offer a great production cost reduction - but Mitsubishi's panel suffered from limited lifetime (15,000 hours).

According to a new report from Japan, Mitsubishi managed to double the lifetime, and their newest panels offer 30,000 hours. This was achieved by new longer-lasing OLED materials and a different device structure. Mitsubishi already shipped panel samples to lighting equipment makers and will setup up their marketing effort soon via their Pioneer JV (MC Pioneer OLED Lighting).

Mitsubishi, Okamura and Taisei developed an OLED desk lamp for office use

Mitsubishi Heavy Industries, in collaboration with Okamura and Taisei, developed an OLED desk lamp for offices. Taisei is constructing a Net-Zero Energy Building (ZEB) in Yokohama, and the OLED lamps will be installed in this building for testing.

The Japanese government has called for new public buildings to be ZEB-compliant by 2020. Lighting takes up about 20% of the electricity in offices so it is a key target for energy saving efforts.

New OLED luminaries are first to use Pioneer and Mitsubishi's printed OLED panels

A few days ago Pioneer and Mitsubishi Chemical announced that they began to mass produce OLED lighting modules made with a "wet coating system". The two Japanese companies estimated that the new process will reduce the cost of the OLED panel by 90% compared to the current production method.

Today I found this nice video showing two new OLED luminaries (the Wireframe and the Magic Tiles Nine) designed by Ely Rozenberg and Mauro Del Santo. This project was organized by Pioneer, Mitsubishi and +ISO and those are apparently the first lamps to use Pioneer's new printed OLED panels.

Pioneer and Mitsubishi begin to mass produce cheap wet-coated OLED lighting panels

Pioneer announced that they began to mass produce OLED lighting modules made with a "wet coating system". The production technology was co-developed by Pioneer and Mitsubishi Chemical. The panels will be distributed by MC Pioneer OLED Lighting Corporation.

The two companies currently produce a single module that is 92.4 x 92.4 mm in size (active area 76x76 mm) and 4.3 mm thick. It weighs 42 grams. The color temperature is 2870K and the maximum luminance is 3,000 cd/m2. Unfortunately they did not reveal the efficiency and lifetime of this OLED.

Mitsubishi developed an OLED panel that can connect to regular E26 sockets

Mitsubishi Electric demonstrated a new OLED lamp that supports the regular E26 ("medium") incandescent socket. This is not the best design for an OLED of course, but Mitsubishi says that one day such a design may be used to replace regular incandescent, CFL or LED lamps.

The OLED is 16x16 cm in size (8 mm thick). Mitsubishi did not reveal any specification on the panel - only that the OLED itself wasn't actually produced by Mitsubishi Electric. The lamp can be rotated independently from the base - so you can change the angle (or rotation) after you screwed the lamp in (this is because the OLED isn't round like normal incandescent or CFL lamps).

Pagination

- Page 1

- Next page