Samsung progresses with its inkjet printing OLED technology, to apply it to next-generation monitors and laptops

According to ETNews, Samsung Display has made significant progress with its OLED ink-jet printing process technology, and the company now aims to apply this technology to produce medium-sized panels for OLED laptops and OLED monitors. Samsung may also use this process to produce smaller tablet displays.

It seems that Samsung is aiming to settle on three main next-generation OLED technologies - evaporation (FMM) OLEDs for small-sized display, ink-jet OLED deposition for medium-sized panels and hybrid QD-OLEDs for large-area OLED TV panels. It's other display technologies are QD-LEDs for TVs and Micro-LEDs for next-generation small and large area displays.

Digitimes details Samsung's QD-OLED TV production plans and equipment

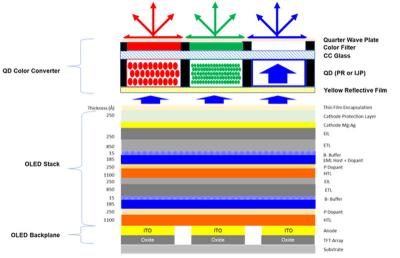

Samsung Display is developing hybrid QD-OLED TV technology, and according to estimates, the company aims to begin trial production in 2019. It is also estimated that Samsung has several challenges to overcome, but according to new reports from Digitimes, Samsung is aiming to start installing equipment for the new fab as early as December 2018.

The new fab will begin operation in the second half of 2019 - pilot production at first which will be expanded to full scale mass production. The new fab will be built in Samsung's L8 LCD production line in Asan, and will take over one of the two lines currently in operation at the fab. Samsung's initial production capacity will be around 25,000 monthly G8 substrates.

ETNews: SDC is building a QD-OLED TV pilot production line

In February 2018 it was first reported that Samsung Display is developing TV panels based on hybrid quantum-dots and OLED architecture (QD-OLED). Samsung later confirmed it is developing such technology, but with no immediate plans to commercialize it.

ETNews now reports that Samsung is now working to establish a pilot 8-Gen line for QD-OLED production. ETNews says that Samsung is collaborating with both Canon Tokki and Kateeva to develop the production equipment - apparently the OLED layers will be evaporated using Canon's machines while the QD filters will be deposited using ink-jet printing equipment made by Kateeva. Samsung aims to finalize the production line by the second half of 2019.

CSoT details its OLED ink-jet printing plans, collaborates with Kateeva, Sumitomo, Merck, DuPont and Tianma

Last month CSoT (TCL) announced plans to establish a 11-Gen LCD+OLED TV fab in Shenzhen, China. Details on the OLED part of that fab were not given, but now we have some updates following the company's investor day.

The new fab will use Oxide-TFT backplanes, and it turns out that the OLED part of the fab will also use the 11-Gen substrates (which may be cut for the actual OLED front plane deposition). Out of the entire capacity of 90,000 monthly substrates, the OLED line will use 20,000 substrates. The fab will start mass production in 2021.

Pixelligent raised $7.6 million, is working with Kateeva to adopt its materials for OLED inkjet printing

US-based high-index material maker Pixelligent Technologies announced it raised $7.6 million in a new funding round that will help the company to further drive its product commercialization and accelerate global customer adoption.

This round was led by the Abell Foundation, and included other Baltimore-based investors. This found also included strategic investments from Kateeva and Japan-based advanced material producer Tokyo Ohka Kogyo.

Prof. Ching Tang and Steven Van Slyke inducted into the US National Inventors Hall of Fame for their work on OLEDs

Professor Ching Tang from the University of Rochester and Steven Van Slyke, currently the Chief Technology Officer at Kateeva have been inducted into the US National Inventors Hall of Fame for their pioneering work on OLEDs. Both Steven and Tang worked on OLED displays as research scientists at Eastman Kodak.

The US National Investors Hall of Fame was founded in 1973, and more than 500 men and women who conceived, patented, and advanced some of the most groundbreaking technological achievements in the United States has been induced so far.

OLED Ink-jet printing market situation, early 2018

Many OLED producers believe that Ink-Jet printing of OLED emissive materials is the best way to achieve lower-cost OLED TV production, and to enable OLEDs to compete in the medium part of the TV market. Ink-Jet printing is an efficient process (less material waste compared to evaporation) and it can be very quick as well. The main drawbacks of inkjet are the limited resolution and the need for soluble emissive materials which are less efficient compared to evaporation ones.

A Kateeva OLED ink-jet printing system

These challenges are being overcome, and it seems that at least four groups (in Korea, Japan and China) are charging forward towards mass production of ink-jet printed OLEDs. Ink-jet printer makers and soluble material suppliers are also optimistic ink-jet printing commercialization will soon be here as the material performance gap is diminishing.

Kateeva officially launches its R&D and pilot OLED TV ink jet printing systems, acquires a large IP portfolio

OLED ink-jet developer Kateeva made several interesting updates regarding its OLED Ink Jet printing technologies. First up, the company formally introduced its inkjet equipment for large-area RGB OLED emitter deposition. Kateeva brands its new line as YIELDJet Explore and these systems are targeted for R&D lines and pilot lines.

Kateeva offers two systems, the Explore, which is used for early development and small panels (up to 200 mm substrates) and the Explore Pro which can be used to produce panels up to 55" in size (this is still a development/pilot system, though). Kateeva announced that it has shipped four Explore systems in 2017, and it expects to ship three additional systems by Q2 2018.

Kyulux recruits Kateeva's Dr. Chris Brown as VP of products

Hyperfluoresence TADF materials developer Kyulux announced that Dr. Chris Brown will join the company as VP of Products. Dr. Brown will lead Kyulux's product development and delivery efforts ahead of the company's anticipated first commercial deployments of TADF and Hyperfluorescence materials in the coming year.

Hyperfluoresence TADF materials developer Kyulux announced that Dr. Chris Brown will join the company as VP of Products. Dr. Brown will lead Kyulux's product development and delivery efforts ahead of the company's anticipated first commercial deployments of TADF and Hyperfluorescence materials in the coming year.

Dr. Brown joins Kyulux from OLED inkjet equipment maker Kateeva, where he was Vice President of Process Engineering. Dr. Brown has been granted 31 US patents and has 34 publications.

BOE to use Kateeva's inkjet printed to establish a pilot OLED TV production line in Hefei

In February 2017 BOE Display announced that will establish a new R&D OLED TV production line in Hefei. According to Digitimes, BOE Display is intending to use an inkjet printing process in this line, and the company already placed an order for an inkjet deposition system from Kateeva last month. BOE will use the systems to produce 55" OLED TVs.

In February BOE announced that the new line will cost 1 billion CNY (around $145 million USD). BOE will invest 80% of the funds, with the rest provided by the Hefei government. Digitimes now states that the new line will only cost 600 million CNY - so it may be that the inkjet printing line is an addition to the 1 billion CNY line (which in that case, will probably be based on an evaporation process).

Pagination

- Previous page

- Page 2

- Next page