![]() The Fraunhofer Institute for Photonic Microsystems (Fraunhofer IPMS) is a research institute dealing with electronic, mechanical and optical components and their integration into devices and systems.

The Fraunhofer Institute for Photonic Microsystems (Fraunhofer IPMS) is a research institute dealing with electronic, mechanical and optical components and their integration into devices and systems.

The Fraunhofer IPMS has been working on OLED since 2000, and in 2009 it launched a new department called COMEDD (the Center for Organics, Materials and Electronic Devices Dresden) to handle its OLED research and pilot fabrication. COMEDD was turned into an independent Fraunhofer Institute in 2012, later it became a business unit at Fraunhofer FEP, and in early 2024 it moved back into the IPMS.

The COMEDD researchers used to develop OLED lighting technologies, and OLED microdisplay technologies. Today most of the focus is into OLED microdisplays.

Maria-Reiche-Str. 2

01109 Dresden

Germany

Researchers at the Fraunhofer IPMS developed a 200,000 nits monochrome OLED microdisplay

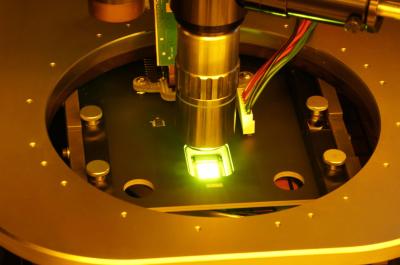

The Fraunhofer IMPS announced that it has developed an exceptionally bright OLED microdisplay, using a novel stack architecture. The new 0.62" SXGA monochrome (green) microdisplay achieves a brightness of 70,000 nits, and on reference substrates it has even achieved over 200,000 nits.

The new architecture uses a 3-stack architecture, which means that three complete OLED device stacks are placed on top of the other. This achieves high brightness, and also reduces the current density for a given brightness compared to a single stack device - and so enhances the lifetime of the device.

Notion Systems and the Fraunhofer IAP team-up to develop EHD printing materials and processes for the display industry

Inkjet printing developer Notion Systems announced a strategic partnership with the Fraunhofer IAP institute to co-develop EHD printing technologies for the display industry. The initial focus of this partnership is to develop new materials and optimizing printing processes for OLED and QLED printing.

EHD utilizes electric fields to precisely transfer inks or other liquids onto substrates. Standard inkjet printing is limited in the deposition resolution, but HED enables very high precision and very small droplet sizes.

Researchers develop OLED-based optogenetic stimulators for neurosensory therapy

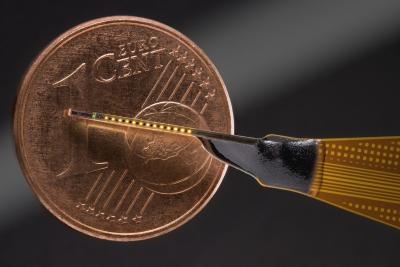

Researchers from the Fraunhofer IPMS, together with colleagues from the Max Planck Institute for Multidisciplinary Natural Sciences (MPI-NAT) are developing OLED-based optical stimulators for future cochlear implants.

The researchers explain that optogenetics is a method that uses light to control genetically modified cells in living tissues. By introducing light-sensitive proteins into cells, their activity can be precisely turned on and off with light pulses. This technique is commonly used in neuroscience to study the functions of nerve cells and to activate or inhibit specific neuronal populations.

The Fraunhofer IPMS manages to increase the transparency of its OLED microdisplays to 45%

A few months ago researchers from the Fraunhofer IPMS announced that they have developed semi-transparent yellow high resolution OLED microdisplays, that are significantly lighter than conventional combiner-based optical see-through near-to-eye systems.

The Fraunhofer IPMS now announced that it has managed to increase the transparency of these microdisplays to 45%.

Researchers at the Fraunhofer IPMS develop semi-transparent OLED microdisplays

Researchers from the Fraunhofer IPMS have developed a semi-transparent high resolution OLED microdisplay, that is significantly lighter than conventional combiner-based optical see-through near-to-eye systems. The specification of the display was not disclosed, but one can see it's a monochrome yellow panel.

The Fraunhofer researchers developed a new semi-transparent OLED-on-silicon microdisplay technology, which enabled the new display. The technology is based on modern and advanced silicon CMOS processes, applied to silicon-on-insulator (SOI) wafers. The new wafer technology can be used to implement very thin circuitry layers. With the help of a specific IC design and an appropriate transfer-to-glass process flow, the transparent OLEDs were enabled.

The Fraunhofer FEP showcases its latest OLED microdisplays at Display Week 2023

During Display Week 2023, the institute demonstrated its latest displays, including the world's highest-density OLED microdisplays, reaching a PPI of 10,000 with a pixel size of only 2.5 um.

Fraunhofer's 10,000 PPI display was e a 0.18" 1440x1080 (monochrome) panel, produced on 300 mm wafers, using a 28 nm backplane process. The Fraunhofer also showcases ultra low-power microdisplays, and more technologies.

The Fraunhofer FEP developed the world's highest density OLED microdisplay, reaching 10,000 PPI

The Fraunhofer FEP research institute announced that it has developed the world's highest-density OLED microdisplays, reaching a PPI of 10,000 with a pixel size of only 2.5 um. The Fraunhofer will demonstrate a 0.18" 1440x1080 (monochrome) OLED microdisplay next week at Display Week 2023.

The new microdisplays were produced on 300 mm wafers, using a 28 nm backplane process. The Fraunhofer explains that most OLED microdisplays to date are produced on 200 mm wafers, using CMOS processes ranging from 90-250 nm. The institutes new technologies enables the the performance increase in OLED display processing.

The Fraunhofer Institute develops ultra-low power OLED microdisplays

The Fraunhofer FEP, in collaboration with GlobalFoundries Dresden Module One and digades, developed an ultra-low power color OLED microdisplay. The researchers at the Fraunhofer say that this display consumes the least power compared to all available microdisplays.

The new microdisplay was developed as part of the Backplane project, funded by the German government (SWMA grant number100392259). The researchers presented a prototype display that features two primary colors and a QVGA (320x240) resolution. The display is based on the Fraunhofer's existing OLED-on-silicon technology, which up until now was used to create monochrome microdisplays.

OLED webinar to introduce OLED lighting manufacturing and R2R production

An AILU (Association of Industrial Laser Users) webinar, scheduled for September 15, will introduce the basics of OLED lighting, discuss the choice for the right substrate and encapsulation material as well as the current status of roll-to-roll processing. The webinar is sponsored by 3D Micromac, the industry leader in laser micromachining and roll-to-roll laser systems.

The webinar will also show results from the EU-funded LAOLA project, which is a collaboration between German and Japanese companies and research institutes. The LAOLA project, led by the Fraunhofer FEP, develops the use of ultra-thin flexible glass as a substrate and encapsulation material in roll-to-roll technology for this purpose.

The Fraunhofer FEP shows its latest OLED technologies, creates a new virtual tour of its facilities

The Fraunhofer FEP Institute published this nice video that shows its latest technology innovations, including its OLED (regular and bi-directional) microdisplays, its new AR/VR optics, flexible OLED lighting panels, its Monarch flexible and transparent OLED panels, sensor and coating technologies and more.

The Fraunhofer FEP also created and published a new virtual tour of its facilities, where you can have a look inside the labs and flexible organic electronics R&D clearnroom.

Pagination

- Page 1

- Next page