TCL starts flexible OLED pilot production at its Wuhan CSoT fab

China-based display maker TCL announced that its 6-Gen LTPS flexible AMOLED production line in Wuhan has commenced operation. The company already achieved some design wins with "top-class" phone makers and is expected to start shipping OLED displays to its customers in Q4 2019.

TCL's production line in Wuhan (which is actually owned by the company's subsidiary CSoT) will have a production capacity of 45,000 6-Gen substrates.

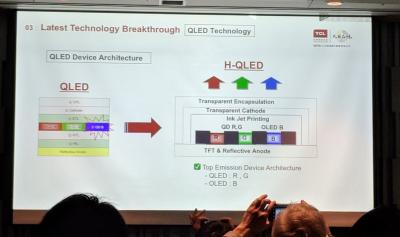

TCL is developing hybrid QD-OLED display technology

TCL unveiled that the company is developing a new hybrid display technology that uses a blue OLED emitter coupled with red and green QD emitters. All three emitter materials will be combined and printed using ink-jet printing technology. TCL calls this technology H-QLED and this could prove to be the technology of choice for TCL's future high-end emissive TV displays.

It seems as TCL believes that commercial-level red and green QD emitters will be achievable in the future, but blue QD emission will be more difficult to develop, and hence it will rely on OLED emitters. TCL did not disclose more details - but this R&D effort is being performed at the company's Juhua Printing platform.

Juhua Printing Display uses Kateeva's OLED ink jet printers

Guangdong Juhua Printing Display Technology was established in 2016 by CSOT and Tianma with an aim to develop OLED ink-jet printing technologies and enable companies in China to collaborate on this technology.

While TCL-owned CSOT already announced that it is collaborating with Kateeva (and others), it was not clear whether Juhua Printing Display was also using Kateeva's printers, but we now have confirmation that indeed the China-based consortium is based on Kateeva's printers. This is obviously a major win for Kateeva, who is also working with BOE and Samsung, among others.

Universal Display announces an OLED evaluation agreement with China's CSoT

Universal Display announced that it has signed an OLED evaluation agreement with Wuhan China Star Optoelectronics Semiconductor Display Technology (CSOT). UDC will supply CSOT with proprietary UniversalPHOLED phosphorescent OLED materials for display applications. UDC did not disclose any more details about the agreement.

Towards the end of 2018, CSOT, a subsidiary of TCL, started construction on its T7 large-area display production fab. The T7 fab, which has a total cost of around 42.7 billion Yuan ($6.15 billion USD), will produce both LCD and OLED displays on IGZO backplanes. CSOT's plan is to start production by the end of 2020 - with real mass production starting in 2021.

South Korea company charged with leaking SDC's flexible OLEDs secret to Chinese display makers

South Korean prosecutors indicted a group of 11 executives and employees of Korea-based Toptec, a Samsung Electronics supplier, accusing them with leaking Samsung's flexible OLED technology to Chinese display makers. The group includes Toptec's president and managing director.

According to Nikkei Asian Review, the Toptec's executives supplied the stolen information to four companies in China - including BOE and CSoT. The cost of the information was 15.5 billion Won - or almost $14 million USD. Toptec produces display production automated equipment.

CLSA lowers its china smartphone OLED production and adoption forecasts

CLSA says that as OLED displays are too expensive for many smartphone makers and lack enough differentiation to LCDs, the company is lowering its OLED adoption forecasts. CLSA now expects China's OLED smartphone shipments to total 116 million in 2018, 143 million in 2019 and 168 million in 2020. CLSA lowered its forecasts by 12-21%. In terms of penetration into the total Chinese smartphone market, CLSA sees 14% in 2018, 18% in 2019 and 21% in 2020.

Looking at the OLED makers, side, CLSA sees ample OLED supply in coming years, which means that expansion is likely to slow. CLSA assumed that OLED makers will achieve 70% yields and a utilization rate of 90%, which will bring all OLED makers to have a combined production capacity of around 288 million 6" panels in 2020. As demand will be only 168 million by Chinese phone makers (and remember there's also Samsung and LGD of course), this will create quite an oversupply situation in China. CLSA cuts its China OLED production forecasts by BOE, Tianma, Visionox, CSoT and Everdisplay by 23% to 26% in coming years.

CSoT breaks ground on its upcoming T7 fab, which includes a printed OLED TV line

China-based display maker CSOT held a ceremony yesterday as it started construction on its upcoming T7 large-area display production fab. The T7 fab, which has a total cost of around 42.7 billion Yuan ($6.15 billion USD), will produce both LCD and OLED displays.

Total capacity in the T7 line will be 105,000 monthly substrates (according to our information, the OLED capacity will be 20,000 monthly substrates). The T7 OLED line will use IGZO backplanes and inkjet printing deposition. CSOT's plan is to start production by the end of 2020 - with real mass production starting in 2021.

CSoT details its OLED ink-jet printing plans, collaborates with Kateeva, Sumitomo, Merck, DuPont and Tianma

Last month CSoT (TCL) announced plans to establish a 11-Gen LCD+OLED TV fab in Shenzhen, China. Details on the OLED part of that fab were not given, but now we have some updates following the company's investor day.

The new fab will use Oxide-TFT backplanes, and it turns out that the OLED part of the fab will also use the 11-Gen substrates (which may be cut for the actual OLED front plane deposition). Out of the entire capacity of 90,000 monthly substrates, the OLED line will use 20,000 substrates. The fab will start mass production in 2021.

TCL/CSoT plans to build a 11-Gen LCD+OLED TV fab in Shenzhen by 2021

TCL announced that its CSoT Subsidiary (China Star, also known as Shenzhen Huaxing Photoelectric Technology) plans to establish an LCD+OLED TV fab in Shenzhen, China. The new fab will have a monthly capacity of 90,000 substrate - and will produce 65- and 75-inch OLED TVs in addition to 65-, 75- and 75-inch 8K LCDs, all on Oxide-TFT backplanes. The line will begin operation in 2021.

The fab will apparently have two different production lines. The LCD line will be a 11-Gen line (3370x2940 mm) while the OLED Line will use smaller 8.5-Gen substrates (although this is not clear, CSoT may aim to use the 11-Gen substrates for OLED deposition too, perhaps cutting these large substrates before the OLED processing. Total investment in this new fab will be 42.6 billion Yuan (or about $6.7 billion USD).

Juhua Printing developed an ink-jet printed 31" 4K OLED panel

TCL announced that Guangdong Juhua Printing Display Technology developed a 31" 4K OLED display. According to the report from Korea, Juhua Printing is using 6-Gen substrate which are cut in half for the organic layer ink-jet deposition which is done at 4.5-Gen.

TCL hopes to finalize the inkjet mass-production technology development by 2019, on 11-gen substrate.

Pagination

- Previous page

- Page 7

- Next page